Today (which happens to be my birthday :-) ) we began building WALLS!

We began by laying out the bottom plate (PT 2x6x16) and the top plate (2x6x16), and the studs (2x6x8, pre-cut to 93") on 16" centers. The areas where studs are currently missing are where windows will go. One of the window headers (a sandwich of 2x6's and plywood) is visible in the above picture.

The picture above shows a framed in window. Jack studs, which span the height from the bottom plate to the header, are first nailed to the sill (using the cripple stud for correct spacing on each side). One of the jack studs is then nailed to its adjacent stud, and the header is put on top. The other jack stud is aligned with the help of the header, and a king stud is put in next to this jack stud. The top cripple stud is measured, put into place, and everything is nailed together.

After all of the studs are nailed in, we sheath the wall with a plywood board. We first nail it in a corner in the center of a stud. We then square up the top and bottom plates along the edge of the plywood. We square everything up to within 1/32 of an inch, and then nail the sheathing to all of the studs (which have been marked on the plywood with the help of a chalk line), headers, etc. We then use a router to cut out the window opening.

Technically the router bit we are using is for cutting laminate, but it was inexpensive and is working well so far. Since we already built the window frames, all we need to do is follow them around with the router and we get a nice, clean, precise window opening.

Voila! Our first complete wall panel. We then mark along the bottom where the J bolts will align. We are very careful to measure correctly both length and width-wise on the bottom plate. We then drill out holes so that we can stand up the panel right onto the J-bolts and drop into place.

We modified the tractor bucket with some custom-made "tusks" to scoop up the panel between studs and do the heavy lifting for us.

We started out with two tusks but later found it was easier to work with only one.

We built two panels (the other one will have an 8' sliding glass door in it) so that they would help stand each other up once raised. The process of getting them in place was a bit hairy, especially because the wind picked up and was catching the panels quite a bit! After some pretty stressful moments, we successfully got the panels into place, tied down the J-bolts, and nailed in bracing. Although the process was challenging (and for me, nerve wracking), we didn't have any major mishaps or errors - though the sill seal kept wanting to blow away...

As a final reassurance, we used the tractor to help hold up the wall since there are some pretty major storms and winds in the forecast for tonight. Here's hoping all our hard work holds firm until we can build more walls tomorrow!

I am really enjoying doing the framing. It is pretty amazing to watch a pile of lumber come together to form real walls and start to make the house take shape! I can stand inside and already envision what the view will be out my windows. It is very exciting! Plus I enjoy all the measuring, sawing, nailing, and drilling, and the pattern of steps we take each time we build a wall panel. It is like a big precise puzzle coming together, all with the work of our own two hands (and some handy tools). Oh, and although I was scared the first couple times I used it, I am in LOVE with the pneumatic nail gun! (And my regular hammering is getting a lot better, too.) Looking forward to building more tomorrow; I think this will actually go pretty quickly!

Research, Conception, Design, Construction, and Outcomes of our (future) green home in Upstate NY.

Friday, July 19, 2013

Bethy's birthday present: Walls!

Monday, July 15, 2013

He already has his shirt off

Today our slab was poured!!! As we predicted, we couldn't get it done as soon as we had hoped, but we were able to schedule for today and luckily the weather cooperated (for the most part - it is really super hot...). Meanwhile, it was okay to have a few days to wait, because that allowed us to implement some extra precautions the mason suggested, such as adding even more bracing to the forms. We also cut up an old hose into small pieces, put duct tape over one end, and put them on the j bolts as little caps so that the threads don't get damaged or dirty. (This was part of our original plan, but at least some of the pressure was off to get it done quickly.)

One of the concerns we were told, however, with scheduling for a Monday was, "I'm not really sure how many guys I can get." We weren't sure what that meant, so we rounded up as many troops for today as we could - myself, Matt, his sister Brigitte, their dad Bob, and my dad Al. We were a little nervous, especially because making a nice smooth slab seemed like it would be pretty different from pouring the footers, and by 7:05 AM there was only one man on site. But within minutes, a parade of pickup trucks arrived, followed closely behind by the first concrete truck, and then things were on their way:

Enough crew showed up that our participation was actually completely unnecessary (which was a bit of a bummer for us), but we stuck around to witness the process and take pictures. See them after the break...

One of the concerns we were told, however, with scheduling for a Monday was, "I'm not really sure how many guys I can get." We weren't sure what that meant, so we rounded up as many troops for today as we could - myself, Matt, his sister Brigitte, their dad Bob, and my dad Al. We were a little nervous, especially because making a nice smooth slab seemed like it would be pretty different from pouring the footers, and by 7:05 AM there was only one man on site. But within minutes, a parade of pickup trucks arrived, followed closely behind by the first concrete truck, and then things were on their way:

Enough crew showed up that our participation was actually completely unnecessary (which was a bit of a bummer for us), but we stuck around to witness the process and take pictures. See them after the break...

Tuesday, July 9, 2013

You remeshin' with me?

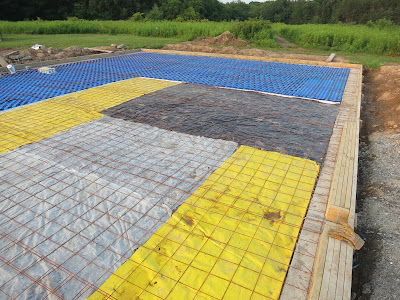

Remember how I said yesterday that the rest of the materials were scheduled to arrive this morning? Well, apparently "morning" means any time before noon, which actually turned into 1PM before anything arrived!!!!So the Roth guys were hanging around for 4 hours this morning with nothing to do. I find this totally inexcusable, but I wasn't there to lay down the law (luckily for the delivery guy). Anyways, once the materials finally showed up, the Roth guys got to work and were able to complete laying the pex tubing today. They also connected all the tubes to a manifold, pressure tested them, and left them pressurized.

We then laid out plastic over the garage area, both to act as a vapor barrier and to prevent the concrete from seeping into the gravel too much when we get the slab poured. We used scrap pieces of plastic - whatever was left over from wrapping the footer foam, empty trash bags, plastic wrapping from large appliances, and my old original Wham-O Slip n Slide from when I was a kid (*sniff.... I shed a little tear for that one. All in the name of recycling!).

This was a pretty easy task, but it still ended up more complicated than I imagined. We made sure to bend up the sharp ends of the steel so that when it was laid down there was no chance of puncturing any of the pex lines. Each of the pieces of remesh then had to be tied together with zip ties (which then had to have their ends trimmed off). Also, there was a bunch of cutting that needed to be done so that remesh could be laid around the drains and plumbing. Overall this wasn't difficult, but it was a bit tedious. We managed to get it done pretty quickly, at least.

|

| The living areas are now complete. |

|

| This is the manifold which will live in the utility room - pretty crazy, huh? |

|

| All done! |

My dad got a head start on laying steel remesh by starting on the end that already had the pex tubing all done and working in tandem with the Roth guys. Once Matt and I showed up after work we helped with the rest.

This was a pretty easy task, but it still ended up more complicated than I imagined. We made sure to bend up the sharp ends of the steel so that when it was laid down there was no chance of puncturing any of the pex lines. Each of the pieces of remesh then had to be tied together with zip ties (which then had to have their ends trimmed off). Also, there was a bunch of cutting that needed to be done so that remesh could be laid around the drains and plumbing. Overall this wasn't difficult, but it was a bit tedious. We managed to get it done pretty quickly, at least.

|

| All ready for a slab! |

Tomorrow our mason is scheduled to stop by to check in on our progress and look it over, and we will get the slab pour scheduled. The weather is looking really fantastic for the rest of this week (0-10% chance of rain each day), so we're hoping to get him scheduled right away! Unfortunately I am concerned that this might be too short notice, especially with the back log of work I'm sure he is dealing with. We'll see.

Updated budget:

+ $373.65 for 47 steel remesh sheets

TOTAL SPENT SO FAR: $47,047.45

TOTAL SPENT SO FAR: $47,047.45

Monday, July 8, 2013

Nerbles

Today, Roth Green Energy came out to start laying the in-floor radiant tubing. I guess a couple of the guys got to the site nice and early, but none of the materials were there yet! When the materials finally arrived, the two Roth guys as well as the delivery guy got to work. However, the delivery guy moved on after a little while, and then one of the Roth guys got called away on an emergency - so that left only one person working on the install! Even so, he managed to get about halfway done today - and then he ran out of materials. So, the next supply is scheduled to come tomorrow morning, and hopefully there will be a team working on it again so that nobody has to work alone. (Well, I guess he wasn't alone - my dad was there observing, and he doesn't like to just sit around and watch without getting involved, so he was able to at least be a gofer.) I stopped by after work to get some pictures:

|

| These are S45 Creatherm insulating panels that help prevent heat loss into the ground. There is 2" of foam in the base and additional foam in the nodules (which we affectionately call "nerbles"), which gives us a thermal resistance value of R10. The nerbles are there so that the pex tubing can simply be walked in and be held in place. By using these panels we get the benefits of a much easier install than having to tie the tubes down to remesh, cleaner (and more avoidable later) pex lines, and double duty as a thermal barrier. |

|

| The huge spool of pex tubing. |

|

| Today's progress. |

|

| As you can see, the panels make for a very clean layout of the tubing. |

|

| Looking good so far! |

Sunday, July 7, 2013

Must... remain... productive...

Although we're at a bit of an impass since we still have to get the radiant floor piping laid by Roth before we get the slab poured, we managed to do a little more work this weekend. The first thing we did was build up the next layer of the forms. We used the 2x6's that had been the insides of the footer forms and stacked them on top of the outside forms, which were still intact and anchored down with the long stakes. We also used this opportunity to recheck level. It turns out we were a little slumped in the middle of the 64' spans, probably due to the kite string sagging. Luckily we are able to make up for that our final forms, and it's much easier to check if these are level since we have a nice sturdy surface to put an actual level on. We then nailed everything together and stuffed any open cracks with some foam.

We then measured out where interior walls will eventually go, and spray painted them with neon green spray paint. Not only does this help us imagine what the floorplan of the house is going to look like, it will also be helpful when Roth comes to lay the heating pipes, since different rooms will constitute different heating zones that can be turned on and off.

We also added thermal breaks around the perimeter for where doors are going to go. It is unwise to have the slab too close to the outside as there is the potential for major heat loss, so we added in a few inches of wood at the doorways as an extra break. Basically we measured some 2x6's to be the width of the door openings, and nailed them all together.

Lastly, we prepped our drains for the slab pour. We stuffed them full of spongy foam, and then cut out solid foam caps of the correct diameter which we then duct taped over the tops of the drains. (These make a great percussion noise when you tap on them.) We also laid a wooden box in the area where the tub drain pipes will eventually go, so that that space will remain free of concrete until later when we install the tub.

I guess now we'll just relax for a few days while Roth comes in and does their work! It is difficult to be patient and wait on other peoples' schedules. But we will at least be busy with making phone calls to our mason to get the slab pour scheduled. Hopefully he's available when we'll want him - with how terrible the weather has been this summer, I expect he is very busy catching up on projects.

Updated budget:

Still the same, because all the wood used for the forms and thermal breaks was reused from before!

We then measured out where interior walls will eventually go, and spray painted them with neon green spray paint. Not only does this help us imagine what the floorplan of the house is going to look like, it will also be helpful when Roth comes to lay the heating pipes, since different rooms will constitute different heating zones that can be turned on and off.

We also added thermal breaks around the perimeter for where doors are going to go. It is unwise to have the slab too close to the outside as there is the potential for major heat loss, so we added in a few inches of wood at the doorways as an extra break. Basically we measured some 2x6's to be the width of the door openings, and nailed them all together.

|

| These are the thermal breaks at the garage doors and front door. |

I guess now we'll just relax for a few days while Roth comes in and does their work! It is difficult to be patient and wait on other peoples' schedules. But we will at least be busy with making phone calls to our mason to get the slab pour scheduled. Hopefully he's available when we'll want him - with how terrible the weather has been this summer, I expect he is very busy catching up on projects.

Updated budget:

Still the same, because all the wood used for the forms and thermal breaks was reused from before!

Friday, July 5, 2013

Compact(or) Parking Only

Yesterday we finished spreading and leveling the gravel that arrived Monday.

We started using the borrowed compactor but had a little issue. First

we had to scramble to try and find a filter for it, because the one we

had with it was caked with dust. It also seemingly turns out the

compactor doesn't like running on water puddles, which with the way the

weather has been this summer is unavoidable. Unfortunately that put too

much strain on the belt, and we killed it. So, luckily, Weider's

Hardware was open (even though it was a holiday), and they had a rental

compactor for about $35 for a day. We quickly snapped it up and got to

work.

You can see that the garage area is raised up a

little from the rest. This is because we won't be getting radiant heat

in the garage, so we won't have pex tubing laid there. So, there is

extra gravel to keep everything level once the slab is poured.

We worked our butts off to get everything done yesterday because we had expected the guys from Roth Green Energy to show up today to start installing the radiant tubing. Unfortunately, we found out this morning that another job ran over (gee, it couldn't have had anything to do with all the rain we've been having, could it? What a summer...), so they couldn't do it today. Hopefully next week. But the work will not stop for us, as we will spend this weekend building forms to prepare for pouring the slab. It's all Up from here!!!

Updated budget:

+ $35.00 for 1 day compactor rental

TOTAL SPENT SO FAR: $46,673.80

|

| Matt Running the Rental |

|

| Nice and Flat |

|

| All done with the gravel! |

We worked our butts off to get everything done yesterday because we had expected the guys from Roth Green Energy to show up today to start installing the radiant tubing. Unfortunately, we found out this morning that another job ran over (gee, it couldn't have had anything to do with all the rain we've been having, could it? What a summer...), so they couldn't do it today. Hopefully next week. But the work will not stop for us, as we will spend this weekend building forms to prepare for pouring the slab. It's all Up from here!!!

Updated budget:

+ $35.00 for 1 day compactor rental

TOTAL SPENT SO FAR: $46,673.80

Tuesday, July 2, 2013

It's Looking a Little Grave....ely Out Here

Monday

afternoon (~1pm) the gravel arrived to set the base of our slab. Matt

had to work until later in the afternoon so it was Bethy operating the

tractor and starting to spread the gravel. To help keep the dust down

we obviously planned on doing it on a rainy day (hahahahaha noooot); the

rain was consistent but not heavy, so the work continued.

|

| Bethy moving the gravel! |

Al

was working on the sewer pipe layout that would be installed under the

slab. The toilet flange, utility room drain, and bathroom shower drain

all needed to be glued up and buried in a trench before we laid gravel

and poured the slab. Bob showed up and helped with digging for the sewer

pipes and spreading the gravel. Just before the final truck load of

gravel showed up, Matt arrived and took over tractor duties so that

Bethy could get back to work.

|

| Matt takes a turn on the tractor |

Josh

arrived shortly thereafter and helped dig for the sewer pipes as well.

As Matt continued spreading and starting to get an even edge, the pipe

was being glued up by Al, and the majority of the trench for the sewer

pipe was dug by Josh and Bob.

|

| A clean pipe is a happy pipe |

However,

as we were just starting to see real progress, the skies opened up and

the rain became so heavy that we had to call it for now. We waited in

our cars for a short while, but when the rain hadn't stopped we called

it a day.

|

| About how we left the site the first day |

Tuesday afternoon, with a relatively dry forecast, Matt and Al got back to work. Matt continued spreading gravel and starting to achieve final grade with the help of some string lines and a level on a stick.

|

| Not too level yet, but we're getting there. |

|

| North wall waste lines |

|

| Nice Pipes!! |

Once

we got the OK from the inspector we began to bury the pipes under dirt,

taking care to tamp down in small layers. We then got out the

compactor which we borrowed from Matt's uncle Ace (Thanks, Ace!!). We

got it up and running and tested it out to see how much compaction we

would get and thus what level we really wanted to be at before running

it.

|

| Testing out the compactor. |

Updated budget:

+ $320.09 for various plumbing supplies

+ $988.20 for 3 trucks of #1 gravel, 14 yds each

TOTAL SPENT SO FAR: $46,638.80

Subscribe to:

Comments (Atom)